In - depth Analysis: The Intricacies of Rim and Tire Assembly

Among the numerous components of a vehicle, the assembly of the rim and tire may seem simple, but it actually encompasses a wealth of professional knowledge and sophisticated designs. From the fitting and sealing of the tire bead to the rim, the precise installation of the valve stem, to the crucial role of the bead seat angle in tire fixation, every aspect is vital to driving safety and vehicle performance. Now, let’s delve into the mysteries through the disassembly diagram of the rim and tire assembly.

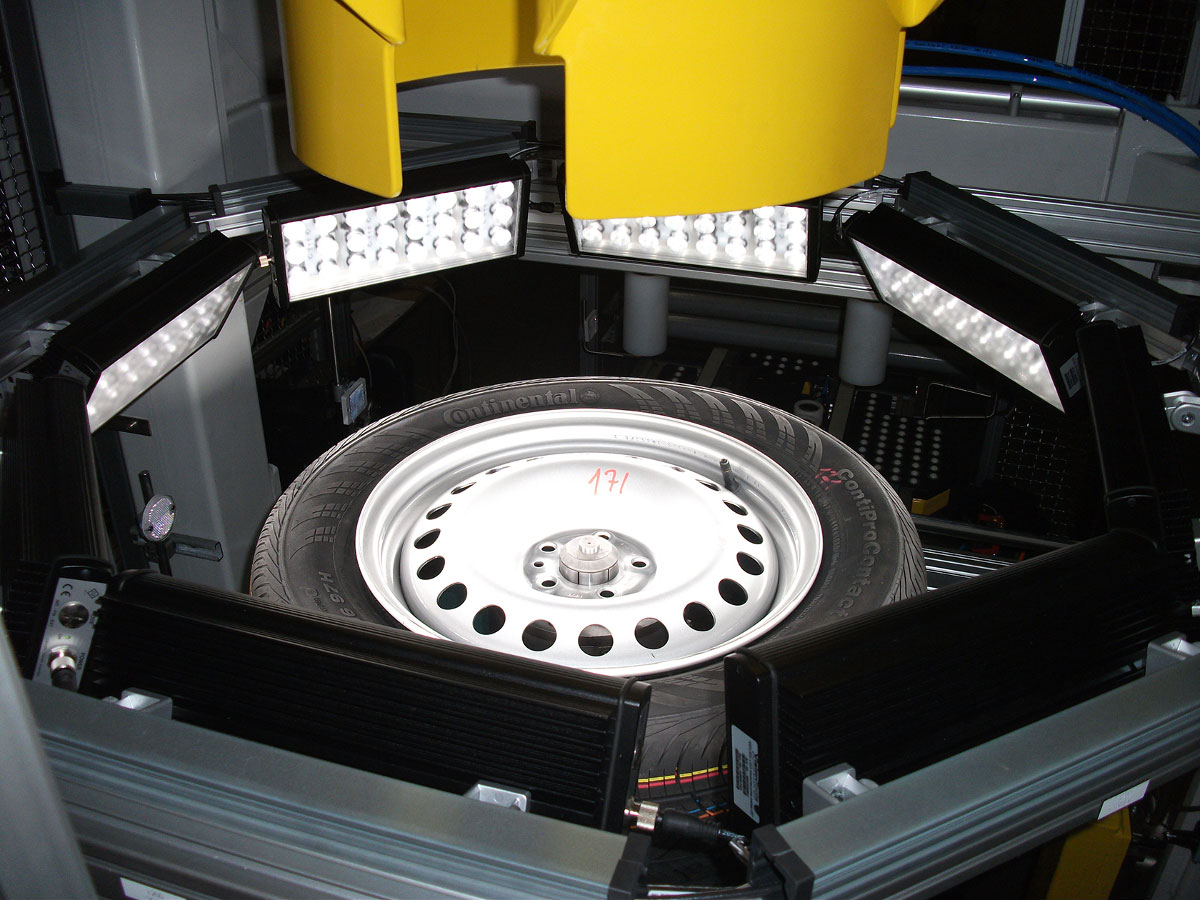

Our match-mark systems offer robust solutions for identifying the match-mark sticker/mark on both the wheel and the tire and aligning the two for high-accuracy matching. We offer a variety of configurations and options, and feature:

- Flexible robotic and traditional high-speed models

- Color Vision Cameras to detect the angle between the wheel and tire sticker/mark

- Automatic rotation of the wheel while holding the tire to the correct angle, with a high degree of accuracy

- Optional Color Audit Cameras to verify correct alignment

- Servo/VFD controlled motions

- Manual, Semi-Auto, and Automatic versions available

Tire Bead Fitting: The Sealing Key for Tubeless Tires

In the modern automotive tire system, tubeless tires are widely used due to their convenience and safety. The sealing structure between the tire bead and the rim edge is the core element ensuring the proper operation of tubeless tires.

When we magnify the joint between the tire bead and the rim edge, we can clearly observe the delicate design. The tire bead, the part of the tire that directly contacts the rim, is usually made of materials with good elasticity and toughness. During the assembly process, the tire bead closely adheres to the rim edge, forming a sealing barrier. The rim edge, on the other hand, is specially designed and processed with a smooth surface and a certain curvature, precisely matching the shape of the tire bead.

The working principle of this sealing structure is based on the balance between the internal air pressure of the tire and the external pressure. After the tire is inflated, the internal air pressure presses the tire bead tightly against the rim edge, further enhancing the sealing effect. At the same time, to ensure the reliability of the seal, special sealants or coatings are often added to the contact surface between the tire bead and the rim to fill any tiny gaps that may exist and prevent air leakage. A good tire bead fit not only ensures the stable air pressure of the tire, extends the tire’s service life, but also improves the driving safety of the vehicle, avoiding dangerous situations such as tire blowouts caused by insufficient tire pressure.

Tire Bead Fitting: The Sealing Key for Tubeless Tires

In the modern automotive tire system, tubeless tires are widely used due to their convenience and safety. The sealing structure between the tire bead and the rim edge is the core element ensuring the proper operation of tubeless tires.

Valve Stem Position: The Precise Docking of the Inflation Port and the Rim

The valve stem, serving as the passage for tire inflation and deflation, is of great significance in terms of its installation position and details on the rim.

First, the position of the valve stem needs to be carefully designed. It should not only be convenient for the driver to inflate the tire but also not affect the overall structure of the rim and the vehicle’s driving performance. Usually, the valve stem is installed at a specific position on the rim. This position must ensure that it will not interfere with other components during the vehicle’s operation and is also easy to locate and operate.

Regarding the installation details, the connection between the valve stem and the rim must be firm and well – sealed. There is a dedicated installation hole on the rim, through which the valve stem is installed on the rim and fixed with nuts or other fastening devices. To ensure sealing, rubber washers or other sealing materials are used at the contact part between the valve stem and the rim to prevent air leakage from the connection during inflation.

In addition, the type and specification of the valve stem need to be matched with the tire and the rim. Different types of tires (such as high – pressure tires, low – pressure tires) and rims of different sizes may require valve stems of different specifications. For example, some high – performance tires may need valve stems that can withstand higher air pressure to meet their special inflation requirements.

Bead Seat Angle: The Key to Tire Fixation in Line with JIS D4218 Standard

The bead seat angle, commonly known as the β – angle, plays a decisive role in fixing the tire on the rim and must strictly comply with the JIS D4218 standard.

The bead seat is the part of the rim that contacts the tire bead, and the design of its angle directly affects the friction and adhesion between the tire and the rim. According to the JIS D4218 standard, a specific bead seat angle ensures that the tire can be firmly fixed on the rim under various working conditions.

When the vehicle is in motion, the tire is subjected to various forces from the road surface, including driving force, braking force, and lateral force. An appropriate bead seat angle enables the tire bead and the bead seat to maintain good contact and friction when the tire is under these forces, preventing the tire from sliding or displacing on the rim. If the bead seat angle does not meet the standard, it may lead to loose tire fixation. When the vehicle is driving at high speed or performing aggressive maneuvers, the tire may risk detaching from the rim, seriously endangering driving safety.

For example, in some high – performance cars or racing cars, the accuracy requirement for the bead seat angle is even higher. Because these vehicles generate greater lateral and centrifugal forces during driving, only a bead seat angle that precisely meets the standard can ensure that the tire remains stably fixed on the rim under extreme conditions, providing reliable grip and handling performance for the vehicle.

Our Robotic Wheel Cleaner are used to automatically clean the location of adhesive weight application on the inside of the wheel prior to weight application.

- Programmable diameter control, with Auto Centering

- Programmable depth control

- Microfiber cleaning

- Programmable “Z” heights for each wheel

The assembly of the rim and tire is a process full of details and science. The sealing structure of the tire bead fit, the precise installation of the valve stem, and the bead seat angle that complies with the standard jointly form a safe and reliable wheel system. Automobile manufacturers and maintenance personnel must strictly follow relevant standards and specifications when assembling the rim and tire to ensure that every link is accurate, providing drivers with a safe and comfortable driving experience.