Wheel Fitment 101: Basic InfoYou Need to Know"

Quick Guide to Upsizing Custom Wheels: A Comprehensive Professional Guide

In the automotive world, upgrading custom wheels is a popular way to enhance both the aesthetics and performance of your vehicle. Here is a detailed guide to help you through the process.

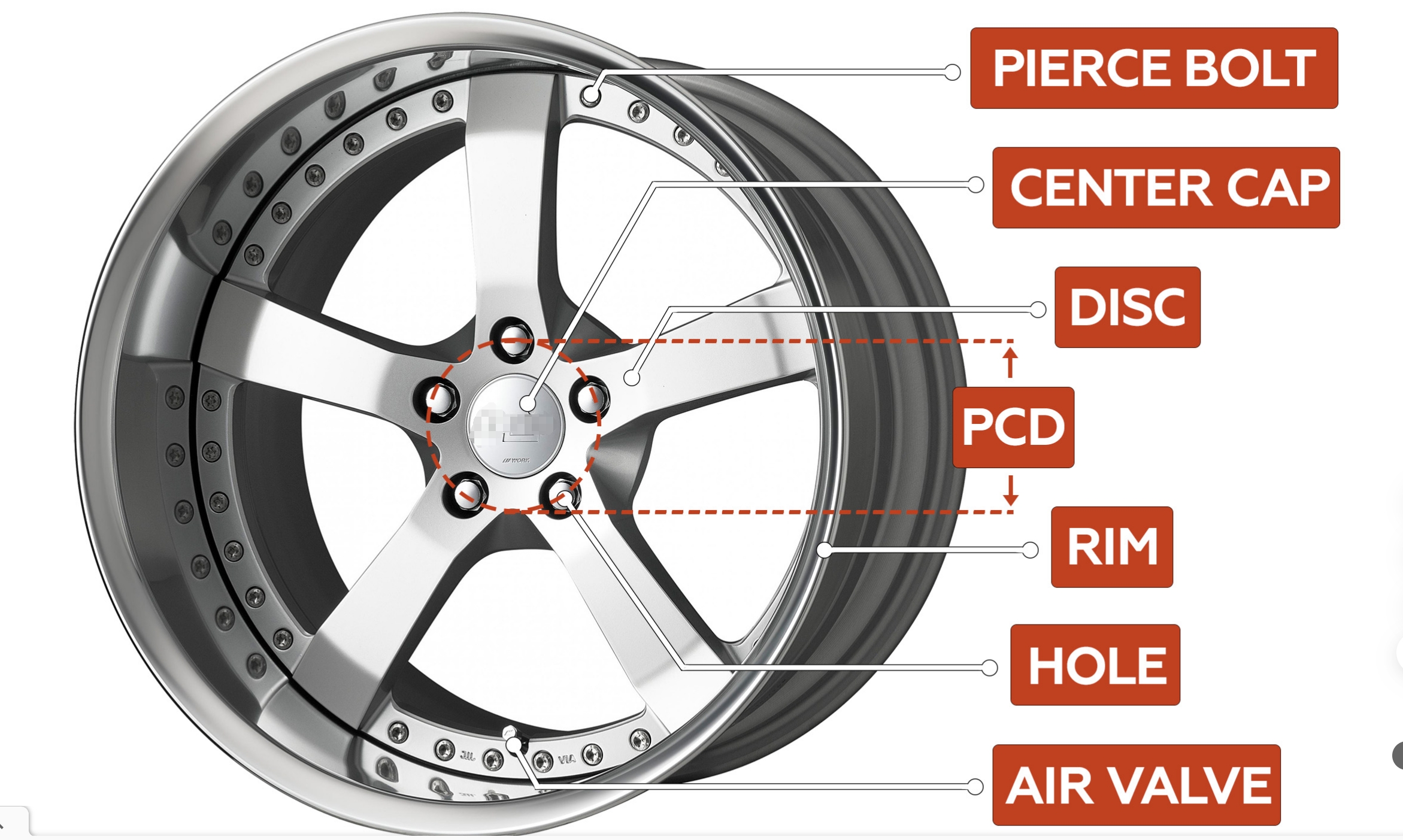

Understanding Wheel Parameters

- Size: The size of the wheel, measured in inches, represents its diameter. For example, a common upgrade might be increasing from a 17-inch to an 18-inch or 19-inch wheel, like upgrading the wheels of the Honda Accord from the original 17 inches. But remember, when increasing the wheel size, you must also replace the tires to ensure proper fit and performance.

- Pitch Circle Diameter (PCD): PCD, measured in millimeters, is crucial. It’s related to the number of bolt holes. For example, 5×114.3 means there are 5 bolt holes evenly distributed on a circle with a diameter of 114.3 mm. The PCD of the modified wheel must match that of the original vehicle exactly.

- Center Bore: This is the hole in the center of the wheel. The diameter of the center bore, also in mm, must be greater than or equal to the original center bore. If it’s too large, a centering ring can be used for adaptation.

- J Value: The J value represents the width of the wheel. For example, an 8.5J wheel has a width of 241.3 mm after conversion, which is most suitable for a 245-width tire, although 235 and 255-width tires can also be used.

- ET Value (Offset): The ET value is the distance from the wheel’s mounting surface to the true centerline of the wheel, measured in mm. A positive ET value means the wheel’s mounting surface is closer to the outer edge of the wheel, giving an obvious outward throw effect. A negative ET value means the mounting surface is closer to the inner edge, showing an inwards concave effect.

Considering Wheel Materials and Processes

Materials

- Steel Wheels: Steel wheels are like a reliable “big brother”. They are low in cost, high in strength, and durable. However, they have poor heat dissipation, are prone to rust, and have a relatively ordinary appearance.

- Aluminum Alloy Wheels: Aluminum alloy wheels are the “fashionistas” in the wheel world. They are lightweight, high in strength, and have good heat dissipation. Wheels made from different forging processes have different strengths and aesthetics and are very popular in the market.

- Carbon Fiber Wheels: Carbon fiber wheels are the “aristocrats” of wheels. They have excellent performance in all aspects, with low weight and high hardness, but their high price limits their popularity.

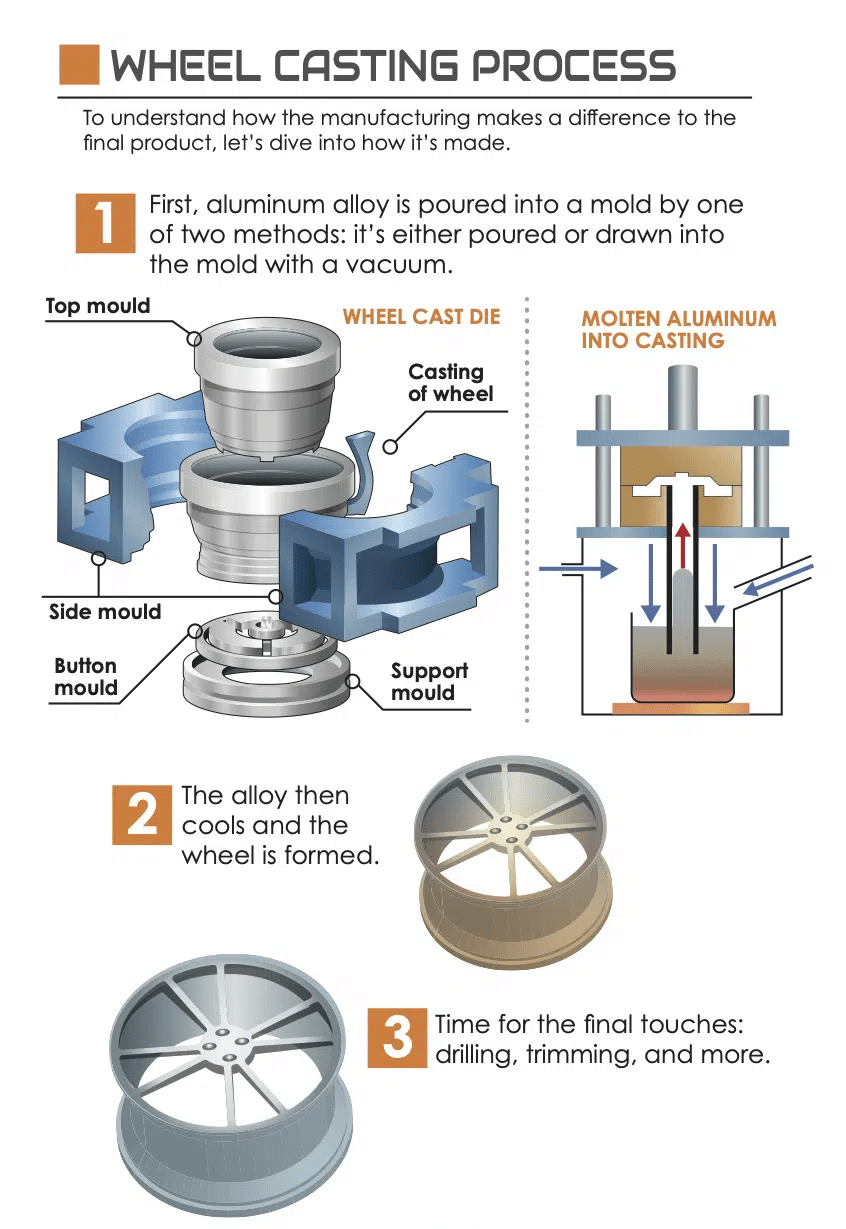

- Processes

- Casting: Casting processes include gravity casting and low-pressure casting. They are relatively traditional manufacturing methods with simple processes and low costs. However, the wheels produced by casting are prone to internal voids and bubbles, which will affect their overall strength.

- Spin Casting: Spin casting is an upgraded version of the traditional casting process. It improves the strength of the wheels, making them lighter and harder than ordinary cast wheels, with good cost performance.

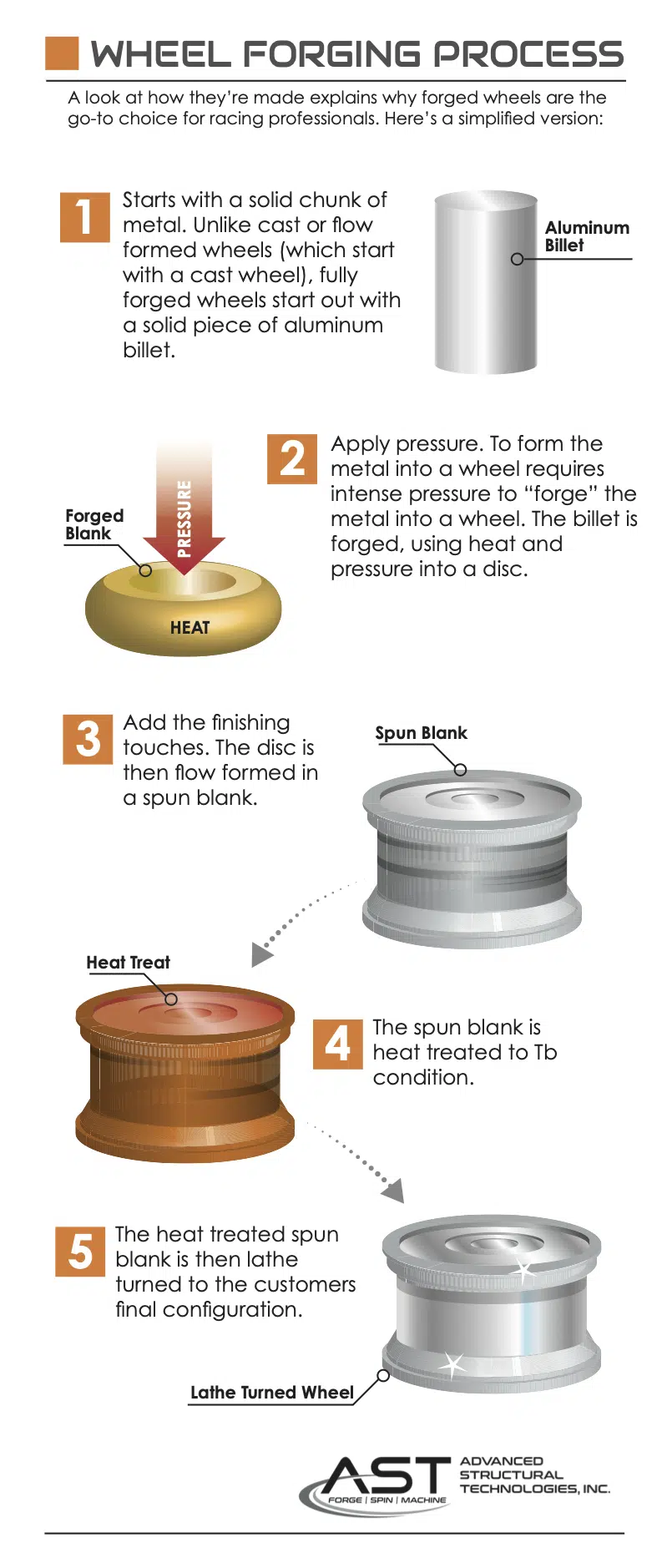

- Forging: Forging is a more advanced manufacturing process. Forged wheels are high in strength, low in quality, and can withstand high loads. They are especially suitable for high-horsepower performance cars, new energy vehicles, and large SUVs.

Selecting Wheel Styles and Designs

- Few Spokes/Openwork: Wheels with few spokes or openwork designs are full of sportiness and vitality, making them ideal for sports cars or those who want to show off their individuality.

- Multi-Spokes: Multi-spoke wheels give a sense of stability and elegance, being more suitable for business-style vehicles or those who prefer a low-key luxury look.

Paying Attention to Tire Matching and Related Issues

- Maintaining the Same Rolling Diameter: When upgrading wheels, if you don’t modify the suspension, keep the rolling diameter of the new wheels and tires similar to the original ones, with an error preferably within 3%. Otherwise, it may affect the normal operation of the vehicle’s speedometer, odometer, and anti-lock braking system.

- Choosing the Right Tire Width: The tire width should be selected according to the wheel’s J value. An inappropriate tire width can lead to uneven tire wear and affect the vehicle’s handling performance.

- Noting the Tire Load Index and Speed Rating: If you often carry heavy loads or drive at high speeds, choose tires with suitable load indices and speed ratings to avoid potential safety hazards.

- Adjusting Tire Pressure: After upgrading the wheels, the tire pressure of the new tires may need to be adjusted. Larger wheels usually require higher tire pressure. It’s best to refer to the vehicle’s manual or consult a professional.

Installation and Subsequent Inspections

- Professional Installation: Wheel upgrading should be done by professional auto modification shops or technicians. They will ensure the correct installation, including wheel fastening, tire inflation, and dynamic balance adjustment.

- Dynamic Balance Adjustment: After installing new wheels, dynamic balance adjustment is necessary to ensure the vehicle runs smoothly without shaking and to reduce tire wear.

- Four-Wheel Alignment: It’s recommended to perform a four-wheel alignment after upgrading the wheels to check and adjust the vehicle’s suspension system parameters, ensuring the wheels are in the correct position for better handling and normal tire wear.